Exemplary Info About What Is A Motor Control

Decoding Motor Control

1. Understanding the Basics

Ever wondered how that industrial robot arm dances so gracefully, or how your washing machine manages to spin your clothes without tearing them to shreds? The secret ingredient is often something called motor control. Now, before your eyes glaze over, let's clarify; we're not talking about your ability to avoid spilling coffee (though that's a valuable skill too!). Instead, we are referring to systems that precisely manage the operation of electric motors.

Think of a motor as a really enthusiastic, but somewhat dim-witted, friend. It has a lot of power, but it needs direction. Motor control is like that wise, guiding voice that tells the motor how to use its energy effectively. It regulates things like speed, torque (that's rotational force, for the uninitiated), direction of rotation, and even protects the motor from overloading or overheating.

Without motor control, you'd be stuck with motors that are either full-throttle or completely off. Imagine a fan that only had "hurricane" and "off" settings! Motor control allows for nuanced operation, adapting the motor's performance to the task at hand.

So, next time you see a finely tuned machine in action, remember that it's likely the unsung hero of motor control making it all possible. It's the brainpower behind the brawn, ensuring smooth, efficient, and safe operation.

Block Diagram.png)

How MCU(Motor Control Unit) Works In Electric Vehicle? Diagram ETechnoG

The Many Faces of Motor Control

2. Exploring Different Types and Applications

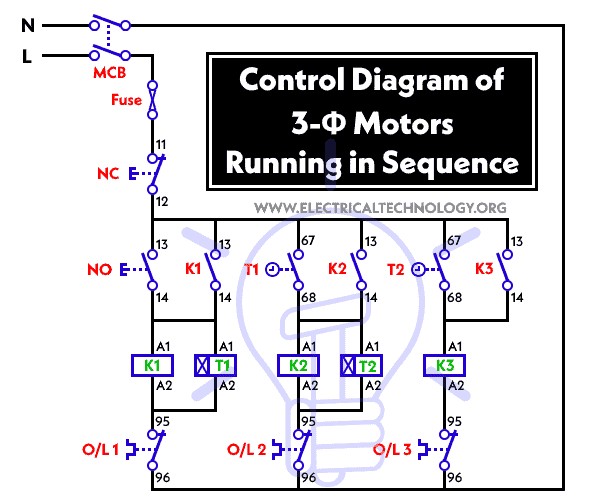

Motor control isn't a one-size-fits-all solution. There are various approaches, each suited to specific needs and applications. From simple on/off switches to sophisticated variable frequency drives (VFDs), the options are as diverse as the motors they control.

Simple starters, like direct-on-line (DOL) starters, are the most basic form. They essentially connect the motor directly to the power supply. While straightforward, they can cause a surge of current when the motor starts, which isn't ideal for all situations. Imagine starting your car engine at full throttle every time not very smooth!

Soft starters, on the other hand, gently ramp up the voltage supplied to the motor, reducing the initial current surge. This gradual start minimizes mechanical stress and electrical disturbances, making them kinder to both the motor and the power grid. Think of it as easing into your morning run instead of sprinting from the get-go.

Then there are the aforementioned VFDs, which are the rockstars of motor control. These devices can precisely adjust the motor's speed by changing the frequency of the power supply. This allows for incredible control over the motor's performance, saving energy and improving efficiency in applications like pumps, fans, and conveyors. They are energy-efficient and provide precise control and the most complex.

Electrical Panel Board / Motor Control Center Wiring Diagram

Why Bother with Motor Control? It's All About Efficiency!

3. The Benefits of Controlled Motor Operation

Okay, so motor control sounds fancy, but why should anyone care? Well, the benefits are plentiful, from saving money on your energy bill to extending the lifespan of your equipment. In essence, it boils down to efficiency, reliability, and safety.

Energy efficiency is a big one. By precisely matching the motor's output to the actual demand, motor control eliminates wasted energy. Think of it like adjusting the volume on your stereo — you wouldn't blast it at full volume if you're just listening to background music, would you? It saves unnecessary energy and noise. VFDs, in particular, excel at this, optimizing energy consumption in variable-load applications.

Reliability is another key advantage. Controlled starting and stopping reduces stress on the motor and connected equipment, preventing premature wear and tear. Imagine the wear and tear reduced on your car if it can start and stop with ease. This translates to fewer breakdowns, less downtime, and lower maintenance costs in the long run.

Safety is also paramount. Motor control systems can incorporate protective features like overload protection, short-circuit protection, and undervoltage protection. These safeguards prevent damage to the motor and protect personnel from electrical hazards, creating a safer working environment.

The Future is Controlled

4. Innovations Shaping the Industry

The world of motor control is constantly evolving, driven by advancements in technology and increasing demands for efficiency and performance. Keep an eye out for these trends shaping the future of motor control.

Smart motor control is gaining traction, integrating sensors, data analytics, and cloud connectivity. This allows for predictive maintenance, remote monitoring, and optimized performance based on real-time data. Imagine your motor telling you it needs a little TLC before it breaks down that's the power of smart motor control.

Another trend is the increasing adoption of energy-efficient motor technologies, such as permanent magnet synchronous motors (PMSMs). These motors offer higher efficiency and power density compared to traditional induction motors, further reducing energy consumption. They are very robust and powerful. They also last a long time!

Also, with increased automation, integration of motors with a single system becomes a breeze. Motor control systems are becoming more tightly integrated with industrial automation systems, enabling seamless communication and coordination between different components of a process. This leads to greater efficiency, flexibility, and control over the entire operation. Imagine a symphony orchestra where every instrument plays in perfect harmony that's the goal of integrated motor control.

As technology advances, it's clear that motor control will continue to play a crucial role in optimizing energy efficiency, improving reliability, and enhancing safety in a wide range of industries. These improvements only benefits everyone and the cost is very minimal.

Motor Control FAQs

5. Addressing Common Queries

Still have questions about motor control? Let's tackle some of the most frequently asked questions to clear up any remaining confusion.

Q: What's the difference between a motor starter and a VFD?

A: A motor starter primarily starts and stops a motor, often with some basic protection features. A VFD, on the other hand, offers much more advanced control, including variable speed, torque control, and energy optimization. It's like comparing a simple light switch to a dimmer switch with smart home integration.

Q: Can I use a VFD with any motor?

A: While VFDs are compatible with many types of motors, it's essential to ensure proper matching and compatibility. Mismatched VFDs and motors can lead to performance issues or even damage. Always consult the manufacturer's specifications and recommendations. Think of it as making sure your phone charger is compatible with your phone you wouldn't want to fry your battery!

Q: Is motor control expensive?

A: The cost of motor control varies depending on the complexity of the system and the specific features required. While initial investment may be higher than basic starters, the long-term benefits of energy savings, improved reliability, and reduced maintenance costs often outweigh the initial expense. It's an investment in the longevity and efficiency of your equipment.