Nice Tips About What Is The Code For Junction Boxes

Decoding the Mystery

1. Understanding the Basics of Junction Box Codes

Ever stared at a junction box and felt like you were looking at a foreign language? You're not alone! Electrical codes regarding junction boxes can seem complex, but they're there for a reason: safety. Think of them as the rules of the road, preventing electrical mishaps and ensuring your home doesn't become a dazzling, but hazardous, light show. We're diving into the world of "junction box codes" to make sense of it all. No electrical engineer degree required, promise!

At its core, a junction box is simply a container for electrical connections. Wires are joined inside, and the box protects those connections from the elements — and prevents accidental contact. The "code" is a set of regulations governing their installation and use. These rules are designed to minimize fire hazards and ensure proper grounding, shielding everyone from potential shocks. It's all about keeping things safe and sound.

The most important code to be aware of is the National Electrical Code (NEC). While not a law itself, the NEC is widely adopted by states and municipalities, becoming the backbone of electrical safety. It's updated every three years, so staying current is important. Imagine trying to drive with rules from the 1950s! You'd be causing some serious traffic jams.

So, how does this translate to the real world? Well, knowing the code helps you determine things like whether you can bury a junction box (spoiler: usually no!), how much space you need around it, and the proper way to secure it. It's practical knowledge for any homeowner or DIY enthusiast who wants to tackle electrical projects responsibly.

Electrical Junction Box Standard Sizes At Tracy Garza Blog

Location, Location, Location

2. Accessibility

Think of junction boxes like buried treasure. You wouldn't want to hide your gold where no one could ever find it, right? Similarly, junction boxes need to be accessible. The code generally prohibits concealing them behind walls or ceilings without providing a way to get to them later. Why? Because if something goes wrong, you need to be able to troubleshoot and fix it without tearing your house apart.

Accessibility usually means keeping the junction box uncovered or providing an access panel. Think of it as a tiny door leading to the electrical heart of your home. This might not be the most aesthetically pleasing solution, but it's infinitely better than having to perform exploratory surgery on your drywall should an issue arise. The electrical inspector will definitely agree!

There are very specific rules about what constitutes "accessible." Generally, the box needs to be reachable without having to remove permanent parts of the building structure or finish. Imagine needing to demolish a wall to get to a loose wire — nightmare fuel!

Consider the placement carefully during any electrical project. Are you planning on finishing a basement? Make sure any existing junction boxes remain easily accessible. Thinking of adding some recessed lighting? Plan for the junction boxes before you start cutting holes in the ceiling. A little forethought goes a long way in preventing future headaches (and potentially costly repairs).

The Right Box for the Job

3. Matching the Junction Box to the Application

Junction boxes aren't a one-size-fits-all kind of deal. Just like you wouldn't wear flip-flops to a black-tie event, you can't use any old box for any electrical application. There are different types designed for different purposes, each with its own set of code requirements. Choosing the wrong one could lead to overheating, short circuits, or even fire. Nobody wants that!

For example, some boxes are specifically rated for outdoor use. These are typically weatherproof or waterproof, protecting the connections from rain, snow, and other elements. Indoor boxes, on the other hand, aren't designed to withstand those conditions and could corrode over time. It's a bit like wearing a raincoat inside — unnecessary and possibly a bit uncomfortable for the raincoat.

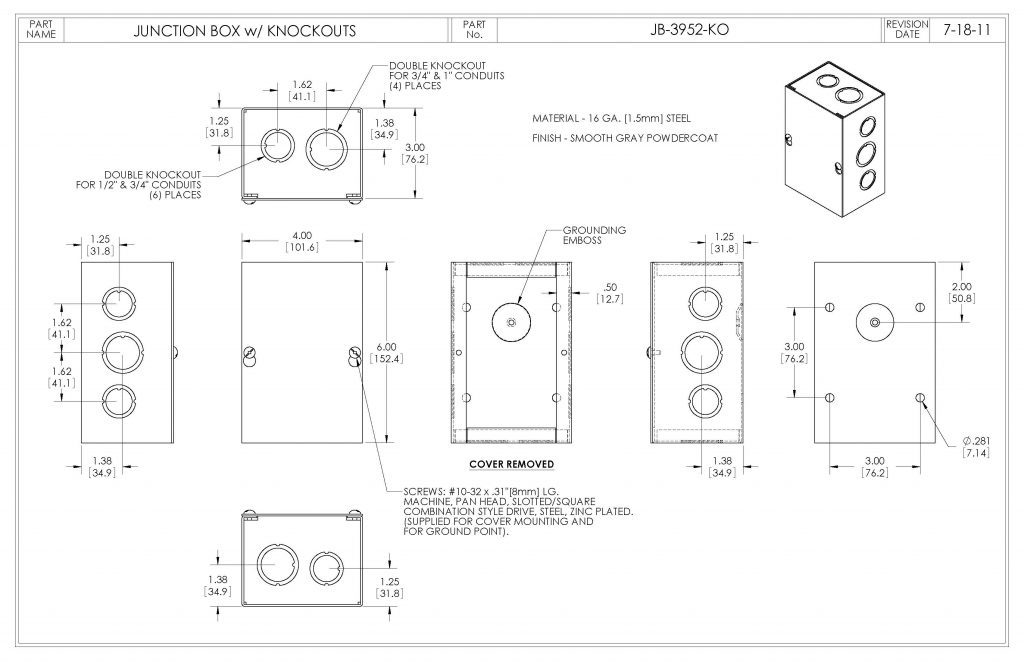

Material matters too. Metal boxes, often made of steel or aluminum, offer better protection against physical damage and can help ground the electrical system. Plastic boxes, while lighter and cheaper, might not be suitable for high-current applications. Think of it as the difference between building a house with bricks versus cardboard — both provide shelter, but one is clearly more robust.

Beyond material and location, you also need to consider the size of the box. This is crucial for ensuring you have enough space to safely make the connections. Cramming too many wires into a small box is a recipe for disaster. Think of it as trying to stuff too many socks into a drawer — eventually, something's going to burst!

Filling It Up

4. Calculating Wire Fill Capacity for Safe Installations

Remember that bursting sock drawer analogy? The same principle applies to junction box wire fill capacity. Every box has a maximum number of wires it can safely accommodate. Exceeding that limit can lead to overheating, shorts, and even fires. Calculating wire fill isn't exactly rocket science, but it does require a bit of attention to detail and a dash of simple math.

The NEC specifies rules for calculating wire fill based on the wire size, the type of box, and the presence of devices like switches or receptacles. Each wire and device is assigned a certain volume, and the total volume cannot exceed the box's listed capacity. Think of it as a puzzle — you need to fit all the pieces (wires and devices) within the boundaries of the box.

Manufacturers often print the box's cubic inch capacity on the inside. You'll need to refer to the NEC or online calculators to determine the volume occupied by each wire and device. It might sound complicated, but there are plenty of resources available to help you through the process. And if you're not comfortable doing the calculations yourself, it's always best to consult a qualified electrician.

Here's a simplified example: let's say you have a box with a capacity of 20 cubic inches. If each wire occupies 2 cubic inches and you have 8 wires, that's already 16 cubic inches. If you also have a device that occupies 4 cubic inches, you're at the limit. Adding any more wires or devices would exceed the capacity and violate the code. A properly sized junction box is paramount for fire safety.

Securing and Grounding

5. Importance of Grounding and Secure Mounting

So, you've chosen the right box, located it properly, and calculated the wire fill. Now what? Securing the box and ensuring proper grounding are the final, but critical, steps in a safe installation. Think of these as the finishing touches that protect both your electrical system and the people who interact with it. A loose junction box or faulty ground can create a dangerous situation.

The code requires that junction boxes be securely mounted to a structural member, such as a stud or joist. This prevents the box from moving or pulling on the wires, which could loosen connections and create a fire hazard. Imagine a dangling box swaying in the breeze — not exactly a picture of electrical safety!

Grounding is equally important. It provides a safe path for electricity to flow in the event of a fault, preventing shocks and protecting equipment from damage. Metal boxes typically need to be grounded to the metal conduit or to a grounding wire. Plastic boxes, on the other hand, usually have a separate grounding terminal for connecting grounding wires.

Always double-check that all connections are tight and secure. Loose connections can create resistance, which generates heat and can lead to fires. It's like a tiny electrical bonfire waiting to happen. Use appropriate connectors and wire nuts, and make sure they're properly tightened. A little extra attention at this stage can save you a lot of trouble down the road. Electrical code compliance keeps everyone safe.

FAQs

6. Common Questions About Junction Box Codes

Still have some burning questions about junction boxes? You're not alone! Here are some frequently asked questions to further illuminate the topic:

Q: Can I bury a junction box in the ground?

A: Generally, no. Junction boxes need to be accessible. There are specific types of boxes designed for direct burial, but they are specialized and must be used according to their listing.

Q: Do I need a junction box for every wire connection?

A: Yes. All wire connections must be made inside an approved junction box. This protects the connections and prevents accidental contact.

Q: What happens if I exceed the wire fill capacity of a junction box?

A: Exceeding the wire fill capacity can lead to overheating, shorts, and even fires. It's crucial to calculate the wire fill and use a box of the appropriate size.

Q: Can I use a plastic junction box for any electrical application?

A: No. Plastic boxes might not be suitable for high-current applications or areas where physical protection is needed. Metal boxes offer better protection in those cases.

Q: Where can I find the specific electrical codes for my area?

A: Contact your local building department or electrical inspector. They can provide you with the specific codes adopted in your area.