Fine Beautiful Tips About Do Brushless Motors Need A Controller

Brushless Motors and Their Need for a Brain (aka Controller)

1. Understanding the Essentials

So, you're diving into the world of brushless motors, huh? Excellent choice! These little powerhouses are incredibly efficient and long-lasting, making them perfect for everything from drones to power tools. But here's the thing: they don't work quite like your average DC motor. They need a little bit of help, a guiding hand, if you will, to unleash their full potential. We're talking about a controller, also known as an Electronic Speed Controller (ESC). Think of the ESC as the motor's brain — it tells it what to do and when to do it. Without it, the motor is essentially just a fancy paperweight.

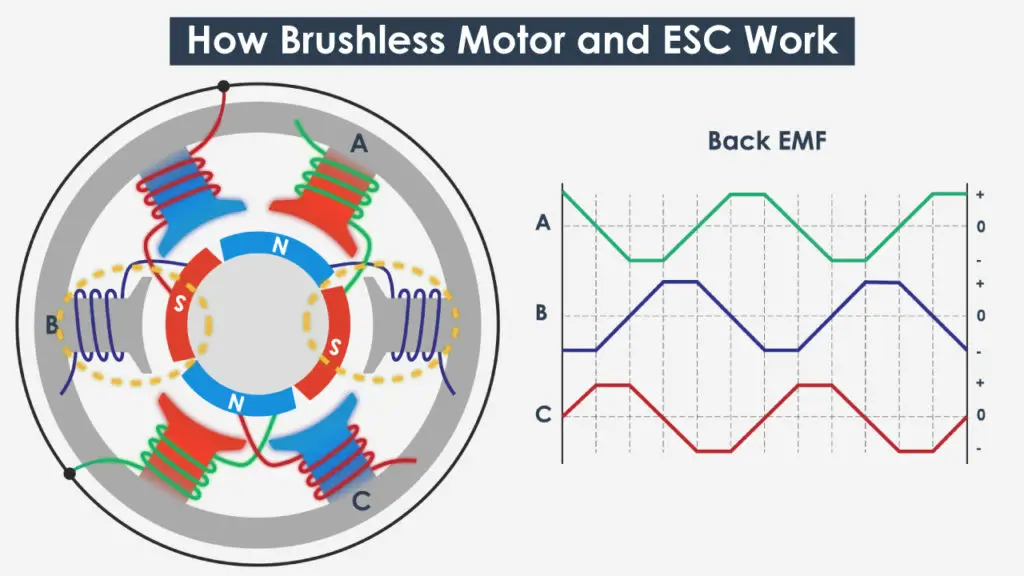

Why is this brain so important? Well, traditional brushed motors have, well, brushes! These brushes physically switch the current flowing through the motor's coils, creating the rotation. Brushless motors, however, cleverly use electronics to achieve the same effect. They don't have those physical brushes that wear down over time. The trade-off? They need a controller to handle all that electronic switching. It's a bit like having a sophisticated orchestra — you need a conductor to make sure all the instruments play in harmony.

The crucial point is that brushless motors don't just need power; they need sequenced power. Imagine trying to push a swing; if you just randomly pushed at any point, it wouldn't swing very well. You need to push at the right moment, and in the right direction. That's what the controller does; it provides precisely timed and directed power to the motor windings to create smooth, efficient rotation. Without this precise control, the motor might twitch, vibrate, or simply not spin at all.

Therefore, to directly answer the question, yes, brushless motors do need a controller. Its not optional. The controller is an essential component that facilitates the motor's operation and provides the necessary timing and sequencing for proper functioning. Attempting to run a brushless motor without a controller is like trying to bake a cake without an oven— you'll end up with a mess and no tasty treat!

How It Works Archives To Mechatronics

Delving Deeper

2. The ESC's Responsibilities

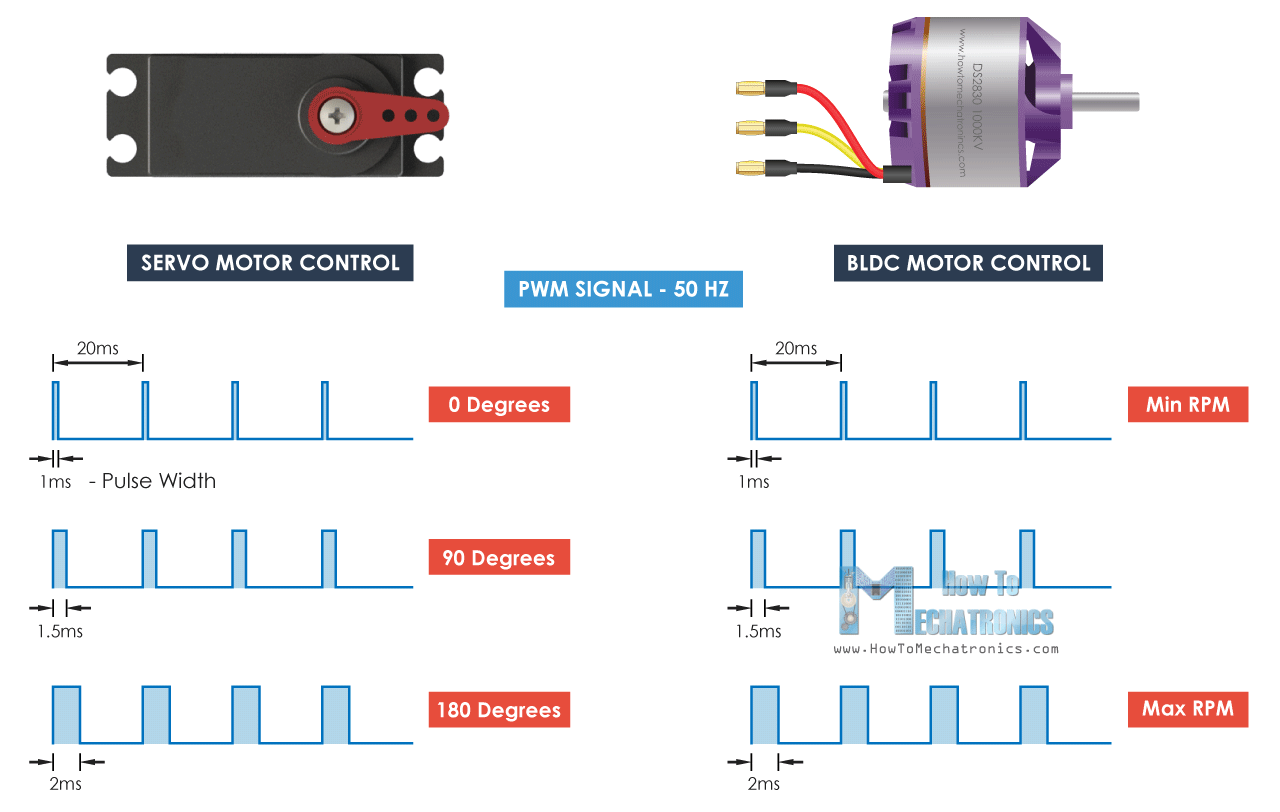

Okay, so we've established that a controller is vital, but what exactly does it do? The ESC isn't just an on/off switch; it's a sophisticated piece of technology that performs several important functions. Primarily, it manages the power delivered to the motor's windings. It regulates the voltage and current to control the motor's speed and torque. Want the motor to spin faster? The controller increases the voltage. Need more torque for a heavy load? The controller boosts the current. It's all about precise modulation.

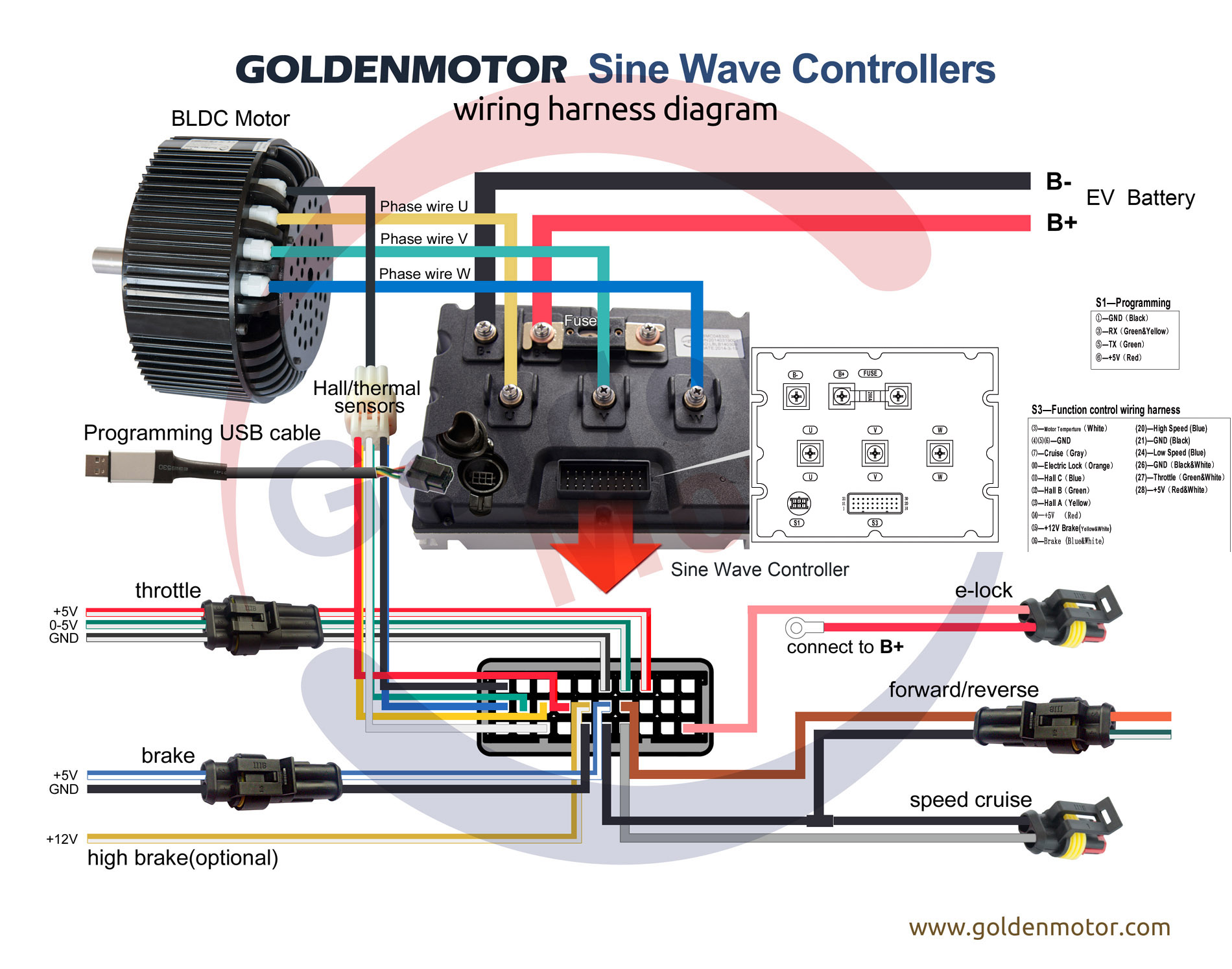

Beyond power management, the controller also handles the commutation process — that electronic switching we mentioned earlier. It uses feedback from sensors (usually Hall effect sensors) in the motor to determine the rotor's position. Based on this information, it energizes the correct coils in the stator to keep the motor spinning smoothly. This commutation process is absolutely critical for efficient operation, and it's all handled by the controller.

Furthermore, many controllers include advanced features like braking, reverse direction control, and even sensorless operation (though this is less efficient). Braking allows you to quickly stop the motor, which is essential for applications like electric vehicles and drones. Reverse direction control lets you change the motor's direction of rotation, offering even more flexibility. Sensorless controllers estimate the rotor's position without using Hall effect sensors, simplifying the motor design and reducing cost, although performance may be slightly compromised.

Think of it like driving a car. The controller is like the accelerator, brake, and steering wheel all rolled into one electronic package. It gives you precise control over the motor's movement, allowing you to fine-tune its performance to suit your specific application. Without it, you're just rolling downhill with no control!

Choosing the Right Controller

3. Matching Motor and Controller

Now that you understand the importance of the controller, the next step is to choose the right one for your motor. Not all controllers are created equal, and using the wrong one can lead to poor performance, or even damage to your motor or controller. The key is to match the controller's specifications to your motor's requirements. This is where a little research goes a long way, but don't worry, it's not rocket science!

The most important factors to consider are voltage and current ratings. The controller must be able to handle the voltage and current required by the motor. If the controller's voltage rating is too low, it could be damaged. If the current rating is too low, the motor won't be able to deliver its full power. Always check the motor's datasheet to determine its voltage and current requirements, and then choose a controller that meets or exceeds those specifications. Its best to err on the side of caution; a slightly over-specified controller is better than one that's pushed to its limits.

Another important consideration is the controller's commutation method. Some controllers are designed for sensored motors (those with Hall effect sensors), while others are designed for sensorless motors. Make sure the controller is compatible with your motor's commutation method. Sensorless controllers are generally more versatile and can be used with both sensored and sensorless motors (although performance may be slightly reduced with sensored motors). However, sensored controllers are generally more efficient and provide smoother operation with sensored motors.

Finally, consider any additional features you might need, such as braking, reverse direction control, or programmable settings. Some controllers allow you to customize various parameters, such as acceleration, deceleration, and braking force. This can be useful for fine-tuning the motor's performance to suit your specific application. Selecting the correct controller is crucial; otherwise, your motor might perform erratically, overheat, or experience reduced performance, impacting the overall functionality of your device. A properly matched controller is an investment in the longevity and efficiency of your brushless motor system.

The Benefits of Using a Brushless Motor with a Controller

4. Unlocking Efficiency and Longevity

Alright, so why bother with all this extra complexity? Why not just stick with simpler brushed motors? Well, the benefits of using a brushless motor with a controller are significant and far-reaching. First and foremost, brushless motors are far more efficient than brushed motors. This means they convert more of the electrical energy into mechanical energy, resulting in longer run times and less wasted energy. In applications like electric vehicles and drones, this efficiency can make a huge difference.

Brushless motors are also much more durable than brushed motors. Because they don't have those pesky brushes that wear down over time, they have a much longer lifespan. This translates to less maintenance and fewer replacements, saving you time and money in the long run. In demanding applications where reliability is critical, brushless motors are the clear choice.

Furthermore, brushless motors offer superior performance compared to brushed motors. They can deliver higher torque and faster speeds, providing more power and responsiveness. This makes them ideal for applications where performance is paramount, such as power tools, robotics, and high-performance drones. And let's not forget the precise control offered by the controller, which allows you to fine-tune the motor's performance to meet your specific needs.

By using a brushless motor with a suitable controller, you gain increased efficiency, prolonged operational lifespan, enhanced performance, and precise control over the motor. These advantages make brushless motors an ideal choice for any application prioritizing durability, performance, and efficiency. Investing in a brushless motor setup ensures consistent, reliable operation with minimal maintenance requirements.

Arduino Brushless Motor Control Tutorial ESC BLDC How To Mechatronics

Potential Issues and Troubleshooting

5. Addressing Common Concerns

Even with the best equipment, things can sometimes go wrong. Let's look at some common issues that can arise when working with brushless motors and controllers, and how to tackle them. One common problem is overheating. If your motor or controller is getting excessively hot, it could be a sign of overloading, improper voltage settings, or insufficient cooling. Make sure you're not pushing the motor beyond its limits, and check that the voltage settings are correct. Consider adding a heat sink or fan to improve cooling.

Another issue is motor stuttering or jerky movements. This can be caused by incorrect sensor wiring, a faulty controller, or interference. Double-check the sensor wiring to ensure it's properly connected. Try a different controller to rule out a hardware issue. Shielding the wires and adding filters can help reduce interference. Sometimes, the problem could be as simple as a loose connection!

If the motor isn't spinning at all, it could be a sign of a blown fuse, a dead controller, or a damaged motor. Check the fuse and replace it if necessary. Test the controller with a different motor (if possible) to see if it's the problem. Inspect the motor for any signs of physical damage. Sometimes, a simple visual inspection can reveal the cause of the problem. If you're comfortable doing so, you can also use a multimeter to check the continuity of the motor windings.

It's worth noting that diagnosing and resolving issues often requires methodical testing and a clear understanding of the motor and controllers operations. Don't hesitate to consult the manufacturer's documentation or online forums for additional guidance. Remember that preventative maintenance, such as regular inspections and cleaning, can help minimize potential problems and extend the lifespan of your brushless motor system.